2010 Mazda 3 2.5 L Low Emissions Intake Manifold

The 2011 Ford Fusion intake manifold that came with the 2.5L swap engine has a variable intake runner control just as the 2006 Mazda 3 2.3 L engine did.

The Fusion intake manifold did not have tumble valves, nor did the 2.3 L throttle body bolt to the intake manifold. The 2.5L throttle body that did have

the correct fitment is not electrically similar to the original Mazda 3 TB. I guessed that a newer 2.5 L Mazda 3 would have tumble valves, a TB that fit,

and a similar control system to the old 2006. That turned out to be a good guess. Prior to this experience, the Mz3 forums were suggesting to use a

aftermarket mounting kit for the old, smaller TB, or to buy a MazdaSpeed 3 throttle body that would fit. It was much less expensive for me to buy the

newer 2.5 L intake manifold and TB. There are still some differences, however.

| Detail | 2006 Mazda 3 | 2010 Mazda 3 | 2010 Ford Fusion |

|---|

| | | | |

| Intake Port Openings (Height x Width) | 35 mm x 48 mm | 40 mm x 48 mm | 40 mm x 48 mm |

| Throttle Body Opening | 65 mm | 63 mm | 63 mm |

| Trim Panel Boss Separation (Center to Center) | 300 mm | 230 mm | 230 mm |

| Intake Manifold to Engine Bolts | 7 | 6 | 6 |

| Variable Intake Manifold Valves | Yes | Yes | Yes |

| Intake Port Shutter Valves | Yes | Yes | No |

| Runner Length and Shutter Valve Solenoids | On Manifold | Off Manifold | Off Manifold |

| Solenoid Vac Ports | Manifold Top | Manifold Side | Manifold Side |

| Solenoid Part Number | Manifold Top | Manifold Side | Manifold Side |

The Intake Manifold gasket set is necessarily different due to the larger ports and the shape of the ports. The intake manifold mounting bolts are all the same length

on the 2010 Mazda and Ford manifolds.

Mounintg 2006 Mazda 3 Solenoids on 2010 Mazda 3 Intake Manifold

The 2.5L Mz3 intake manifold does not have the IMRC and VTCS solenoids up on top of the manifold. The vacuum hose bungs on the plastic intake manifold are

different as well. I had to remount the 2006 solenoids on the 2011 intake manifold, which I did by riveting the two solenoids together and then making a

custom sheet metal mount that used existing bosses on the 2011 intake manifold near the actuators. The photo below shows the final configuration, except I

later cut down the vacuum hose lengths

Variable Tumble Control System (VTCS) / Variable Tumble Shutter Valve (VTSV)

What is it and what does it do?

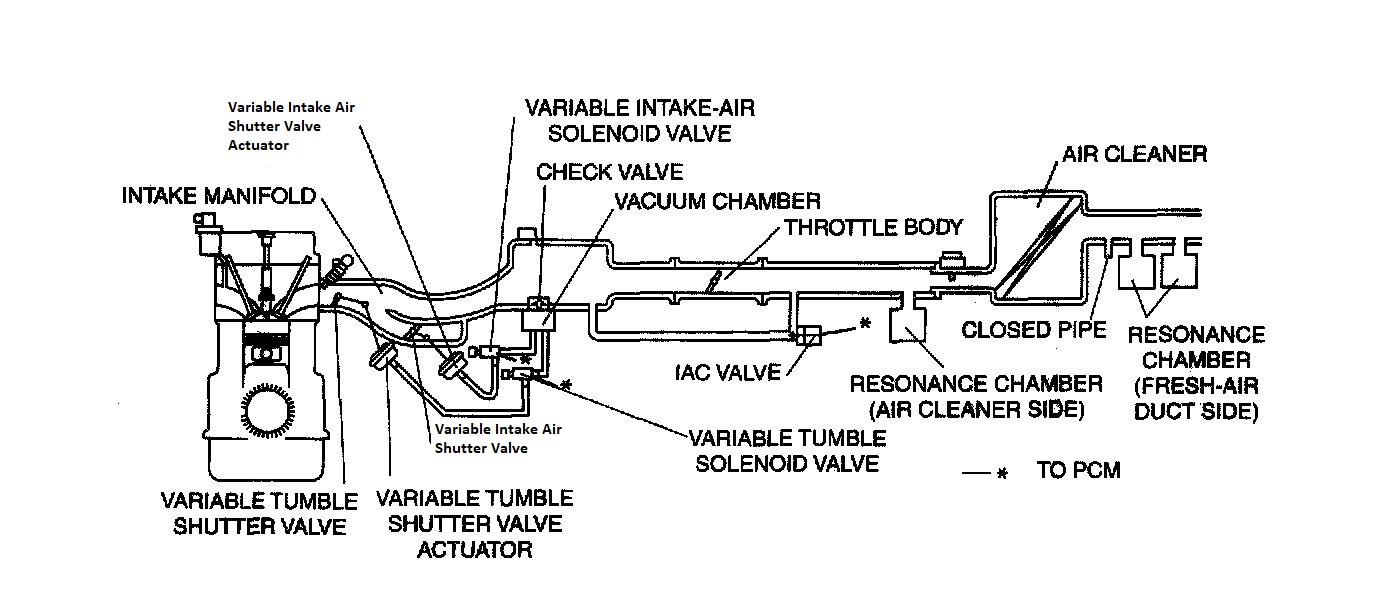

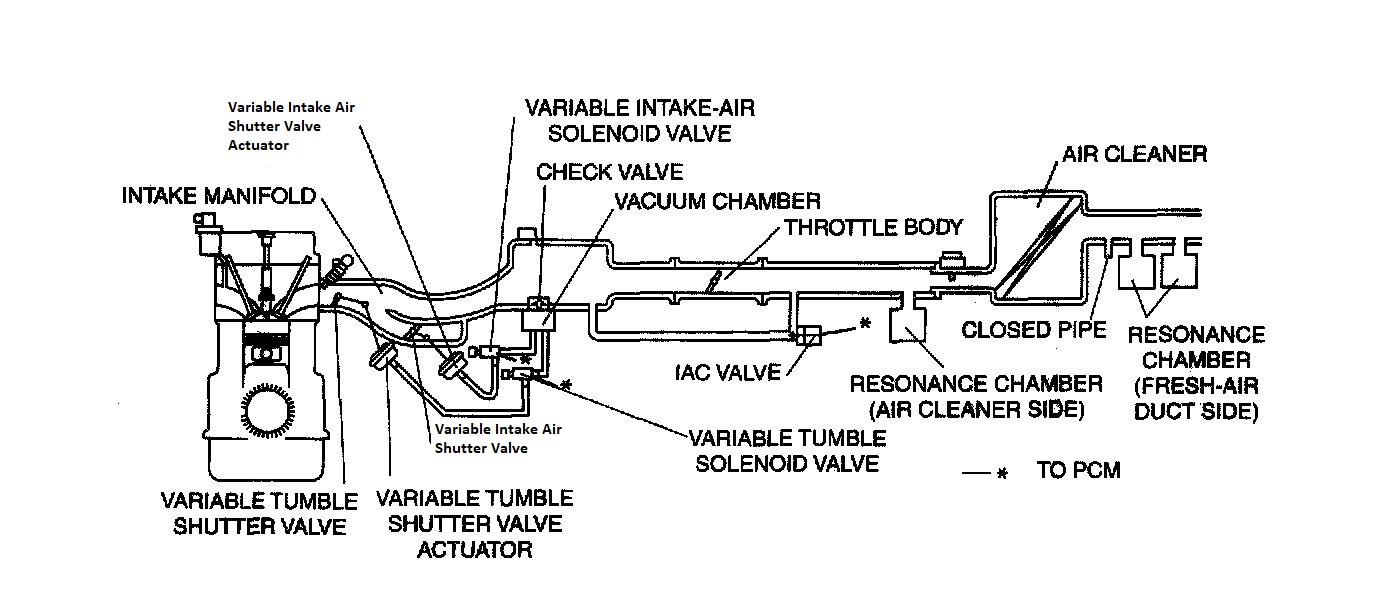

The VTCS system is a set of plates on a steel shaft, a vacuum solenoid, vacuum hoses, and a vacuum actuator that restricts airflow to the engine through

the intake manifold to improve emissions through increased combustion efficiency under low-load (< 3,750 RPM) situations. The system is necessary because

the variable valve timing system for the Duratec 2.3L and 2.5L engines uses a variable timing, fixed valve lift system. The relatively high, but fixed,

valve lift of the system creates a need for VTCS to increase air speed into the combustion chamber under low load; where a variable lift system would

normally serve this purpose.

How does it work?

The system responds to an electrical signal from the Powertrain Control Module (PCM) when the PCM detects a low-load situation during normal engine

operation. The electrical signal is sent to the VTCS control solenoid, which opens a normally-closed valve thus exposing the VTCS vacuum actuator to

low pressure from the intake. The VTCS actuator contains a diaphragm that responds to the higher pressure ambient air on one side of the diaphragm

by pushing an actuator arm towards the low pressure side of the diaphragm. The actuator arm is connected to a steel shaft with throttle plates, one

for each intake manifold air runner, that runs horizontally through the intake in parallel with the long axis of the head. Each throttle plate is

fixed to the steel shaft so that they open and close together. As the plates close, they restrict air flow to the intake valves to a small cut-out

area at the top of the plate. As the air flow is restricted, its pressure and thus its speed increases. The purpose of this restriction is to create

a small, fast stream of air that flows across the open valve and tumbles into the combustion chamber where it mixes with fuel more completely. The

increased combustion efficiency results in less harmful emissions and increased fuel economy. At higher loads, the air restriction would be

counter-productive, so a spring in the vacuum actuator is used to keep the plates in a neutral position. Even in the neutral position, there would

be some disruption of the air flowing into the cylinders, which has led some owners to want to remove the plates. I know of no dyno test results

that address keeping vs. removing the plates.

Locations

On cars that have VTCS, the control solenoid is located at the top of the intake manifold to the right of the IMRC solenoid. On later cars, the solenoid

will be on a steel bracket closer to the actuator side of the intake manifold.

Failure modes

The PCM monitors the functioning of the system through a single VTCS position sensor. The sensor is really a switch that senses contact or no contact from

the vacuum actuator arm. Below are some common problem areas associated with the system.

The most common cause of problems is when the vacuum line that connects the control solenoid to the vacuum actuator or the intake manifold to the control

solenoid splits and prevents the actuator from functioning.

If the intake manifold has been removed, it is not uncommon for the plastic arm that activates the position sensor to break. The system will still function

correctly, but a P2006 code (Tumble Valves stuck closed) will be thrown by the PCM. Mazda's position is that the only way to fix this problem is to buy

a new intake manifold.

In the course of normal operation, all of the plates will be in either the open or closed position as they are fixed to a single steel shaft that runs

horizontally through the intake manifold. One failure mode of the system occurs when one of the fixed plates becomes loose on the steel shaft. Additional

problems can result if the plate seperates from the shaft and is pulled into the head or combustion chamber.

Since Mazda used the exact same connector for these two solenoids that are normally located inches from each other, it is quite easy to get them

mixed up. You should get a P2004 IMRC stuck open code. The car will also be doggy slow below 5,000 RPM, and then feel like the turbo just spooled from

5,000 RPM until redline. The car will also run lean and ping lightly.

Parts

The IMRC and VCTS solenoids are exactly the same part: Dorman 911-907

You can find the solenoids for less than $10 each on eBay. The same solenoid is also a canister purge or EGR solenoid on Fords.

| MAP Sensor (Same Part Number) |

|---|

| 2006 Mazda 3 | 2010 Mazda 3 |

|---|

| The VRef for this sensor is shared with the VTCS sensor |

|

|

2006 Mazda 3 VTCS actuator modified to mount on 2010 Mazda 3 intake manifold. (Looking into intake manifold port)

2006 Mazda 3 VTCS actuator modified to mount on 2010 Mazda 3 intake manifold. (Looking across the intake ports)

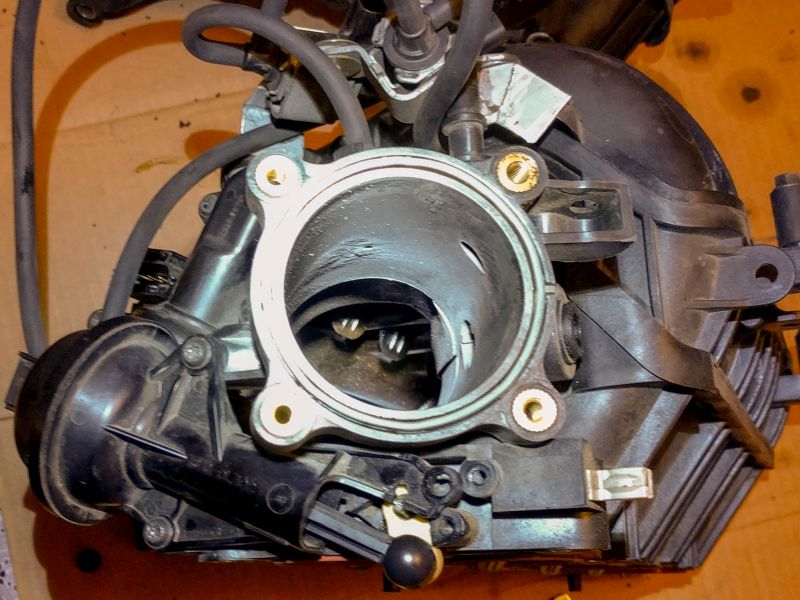

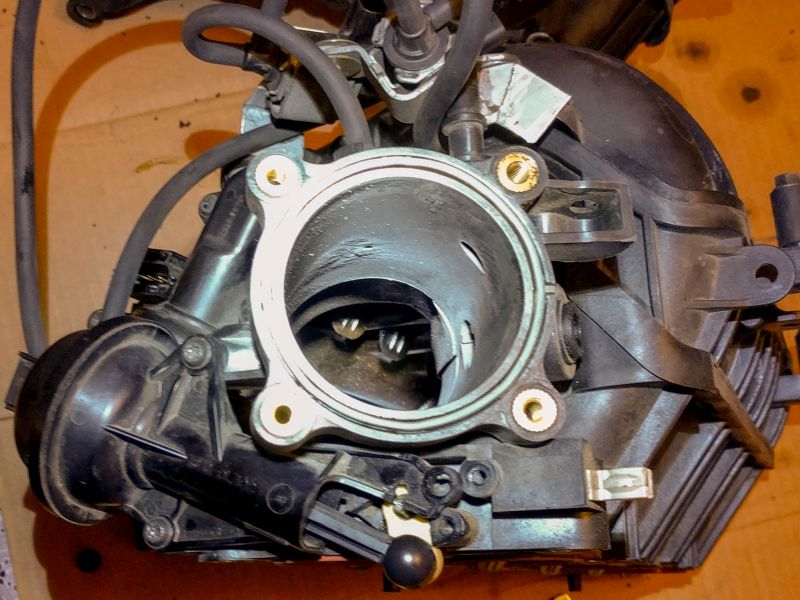

A view down the throttle body opening on the intake manifold showing the intake manifold control valves (IMRC valves). The valves are normally open,

producing a resonant chamber that is akin to having a longer runner. The valves close at 5,000 RPM to simulate a shorter runner.

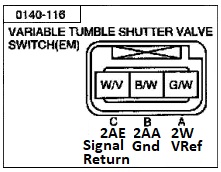

The drawing below is looking into the 2006 VTCS connector that plugs into the 2003 Mazda 3 intake manifold's VTCS vacuum actuator. This connection to the vacuum actuator is used to tell

the PCM the position of the VTCS actuator. On the 2006 sensor (essentially a potentiometer), the minimum expected voltage is .2v when the actuator is being pulled

closed by the PCM. on the 2010 Mazda 3 intake manifold VTCS actuator, the value only drops to .4v and flags an error in the PCM:

P2004: Intake Manf Runner Control Stuck Open bank1

W/V = White / Violet

B/W = Black / White

G/W = Green / White

Last update: Dec 7th, 2019