The major cost failures that have occurred with the truck pertain to the transmission. The input shaft seal was leaking

and that required 9.5 hrs. of labor to replace. Then, when the transmission (really the torque converter) failed,

the resulting transmission rebuild was costly as well.

The Ball Joints are a known failure point, and although this model was not included in the recall, they are the same parts that failed on the 2000 model.

Other than the transmission, there are some oddities of the design. The first is the leaky water outlet at the top of the intake that accepts

the upper radiator hose. It's a stamped steel part of the lowest possible design quality, which makes it very difficult to seal. The technique

that has worked best for me is to coat the paper gasket with a light coat of blue RTV and let the RTV almost dry, then seal the parts. A silicone

gasket would probably be ideal. The real fix is to replaced the stamped steel part with a machined aluminum part. I have been told that over-torquing

the bolts can warp the steel and cause a leak, but I always use a torque wrench and it will still leak with only the paper gasket installed.

Another repeated failure point is the MAP sensor attached at the top-center of the intake manifold. When it fails, the truck will start easily, but

will not continue running without keeping a foot on the accelerator at all times. The cost for a new part is over $80 and it will fail readily if

one washes the engine and gets it wet. Again, this is a design failure, or perhaps a part quality problem. MAP sensors rarely have failed on my

Fords.

Finally, the surprise failure was the PCM. This model has a high failure rate for the PCMs. The truck would get warm and stop running mid-drive.

This happened to me a couple of times while towing up a hill -- bad stuff. After replacing the PCM, I routed a racing brake vent hose up from the

passenger side fog light hole (my Durango does not have fog lights) to the engine compartment to blow air on the PCM. I did have to cut a hole through

the sheet metal in the engine compartment to accomplish this.

| Problems |

| Date | Miles | Difficulty | Issue |

| |

| 9/2002 | 54,902 | Med | Intake Coolant Outlet Gasket |

| 11/2002 | 59,782 | Easy | MAP Sensor Failure |

| 1/2004 | 68,862 | Easy | Turn Signal Flasher |

| 10/2004 | 75,905 | Easy | Differential Speed Sensor |

| 10/2004 | 76,006 | Med | Front Door Latch Mechanism |

| 10/2005 | 85,012 | Hard | Pitman Arm, Idler Arm, Upper and Lower Ball Joints |

| 9/2006 | 95,870 | Easy | MAP Sensor Failure |

| 9/2006 | 96,027 | Med | Rerouted Coil Wire per TSB |

| 9/2006 | 96,027 | Dealer | Flashed PCM TSB 18-004-02 |

| 9/2006 | 96,027 | Med | Replaced Transfer Case Seal |

| 9/2006 | 96,079 | Easy | Accesory Drive Spring Tensioner |

| 9/2006 | 96,184 | Hard | Replaced Transmission Front Pump Seal |

| 10/2007 | 110,704 | Hard | Replaced Water Pump |

| 10/2007 | 110,704 | Easy | Replaced Radiator Cap |

| 10/2007 | 110,704 | Med | Replaced Water Pump Bypass |

| 10/2007 | 110,704 | Med | Replaced Thermostat |

| 10/2007 | 110,704 | Med | Intake Coolant Outlet Gasket |

| 10/2007 | 110,704 | Easy | Replaced Serpentine Belt |

| 12/2007 | 113,601 | Med | Intake Coolant Outlet Gasket |

| 4/2008 | 118,297 | Med | Intake Coolant Outlet Gasket |

| 7/2008 | 122,172 | Easy | Replaced PCM |

| 11/2008 | 124,474 | Med | Replaced Radiator Upper and Lower Hoses |

| 11/2008 | 124,474 | Easy | Replaced Radiator |

| 11/2008 | 124,474 | Easy | Replaced Electric Door Latch |

| 2/2010 | 135,601 | Hard | Replaced Transmission - Martin Saine |

| 4/2010 | 136,165 | Med | Replaced Transmission Lines (2) |

| 12/2010 | 140,222 | Easy | Replaced Rear Hatch Supports |

| 6/2012 | 148,617 | Hard | Replaced Steering Gear |

| 6/2012 | 148,617 | Med | Replaced Power Steering Hoses |

| 6/2012 | 149,032 | Med | Replaced Inner and Outer Tie Rod Ends |

| 7/2012 | 149,032 | Easy | Replaced Valve Cover Rubber Grommets |

| 7/2012 | 149,032 | Easy | Replaced PCV Valve |

| 7/2012 | 149,032 | Easy | Replaced Valve Cover Breather Elbow |

| 7/2012 | 149,032 | Easy | Replaced Passenger Side PCV Hose |

| 7/2012 | 149,032 | Hard | Replaced Exhaust Fasteners |

| 7/2012 | 149,032 | Med | Repaired Aux Power Outlet Wiring |

| 7/2012 | 149,032 | Med | Front End Alignment and Centered Steering Wheel |

~100,000 miles PCM Failure

While towing a trailer up a very steep, narrow, two lane road, the engine suddenly quit and could not be refired. Fortunately,

the road wasn't very busy, so the occasional car could easily drive around. The problem seemed electrical at the time. The coolant

temperature was also somewhat higher and this was a very hot day and the A/C was on. Subsequent attempts to refire the engine mostly failed.

After the engine cooled down, the Durango would again start and I could drive some more. I had certainly seen that sort of problem before

with magnetic sensors (crank and cam sensors) and suspected that the Durango had a crank sensor that was keeping the PCM from detecting

cylinder #1. I was mostly able to accomplish my mission that weekend, but ended up have the whole rig towed when it happened again and

letting it cool for 20 minutes didn't fix the problem. It got to the point that driving the vehicle for just a few minutes would cause

the failure. So to test a theory, I put a bunch of ice in a zip-lock bag and set it next to the PCM. Bingo! I could drive it as far as

I needed to as long as the PCM was kept cool.

The online Dodge forums seem to indicate that most 1998-1999 Durangos had PCM problems. I bought

an exchanged PCM from a place in Florida through eBay. The first one had security enabled, but since my D has no security features, it

wouldn't work. Apparently the security code is in the BCM on security enabled Durangos and the PCM needs to communicate with the BCM before

the vehicle will start. So I returned the first one and the second one has worked well. Interestingly, the lean mixture problem, seen as

pinging, went away with the new processor. The truck performed better than it had ever performed. It was like new.

~120,000 miles Transmission Failure

The transmission started to slip while towing a trailer. The slip was initially only detectable by increased transmission temperature. The temp would

rise very quickly on steep uphill sections of road. I pulled over several times to think about what could be happening. Finally, I got impatient

and drove it hot until the Dodge Transmission over-temp light went on. I can guess that the light doesn't come on until 280-300 degrees F! That's way too

late. I pulled over immediately and came to the conclusion that

the torque converter must be slipping and generating all of that heat.

Some interesting notes:

Dodge is doing their customers a great disservice in not triggering the over-temp light sooner.

Having a real temperature gauge is as important as I first suspected that it might be

Having two senders is worth the effort (the after cooler temps weren't that unusual, but the post TC temps were very high)

This time, I was able to drive the truck home, then fetch the trailer with a borrowed truck without having to pay for a double tow (truck and trailer).

Since the temps stayed normal during ordinary street driving, I thought all I would need is a new TC. So I took the Durango to a local transmission shop.

I had previously read online to never get the transmission flushed, and especially not when a problem was suspected, so I told the counter girl to just

drop the pan and replace the filter and gasket and check the pan from damaged parts. I didn't know what they did from that point, but when I got

the truck back, it wouldn't shift correctly any more. It was slipping right after leaving the parking lot. This was after the owner had told me that

it was a great shifting truck after the initial test drive. He denied all of this and refused to refund the money after basically junking my truck!

So, now I know where not to go to get a transmission repaired. I suppose that's something. So I looked on the internet for a builder with good reputation.

I found one in Martin Saine. I talked to him via email and we worked out what the best configuration would be for a tow-only Durango. I had to have the truck

transported to his shop, so I used a service called uBid.com to find a transporter. I was very happy with the transporter company uBid identified. In the end,

doing it this way cost me an extra $600.

~120,000 miles New Transmission Leaks

When the transporter brought up the fixed Durango, it was leaking badly. All around the pan gasket it was very wet and the

LE Monolec was expensive syrup to be losing. So I contacted Martin and he asked me to check the

line fittings. It turned out that the line fittings were leaking so he sent me a new set of lines and case fittings. The interesting thing about this leak is

that it doesn't leak until the vehicle has been sitting for a couple of days. It makes me think that either the fluid is pooling up some place, or that the fluid

is draining back into the pan and then starts to leak out of the pan seal.

It turned out that the transmission oil pan had a stripped bolt hole. I attribute this to the transmission shop that initially damaged the transmission.

Martin had noticed a stripped hole when he removed the pan at his shop and had inserted a longer bolt in one of the pan corner holes. It turns out that the

one of the holes adjacent to that corner was also stripped. I inserted a longer bolt and torqued all of the pan bolts down using my shiny new Craftsman

in/lb torque wrench to 156 in/lbs per the manual.

~120,000 miles Sluggish in First Gear

After a few times driving the Durango around, it stopped kicking down into first gear at stops. I could still shift it with the lever, or by tromping on the

go pedal, but not by itself. Martin suspected either the TV cable needed a small adjustment or a solenoid in the valve body was bad.

To adjust the TV kick-down cable:

Remove the white clip on the TV cable coming off of the throttle body.

Move the throttle body lever to its most extreme open position

Check to see if the cable deflects ¼" to ½"

Put the white clip back on

Let go of the throttle body lever

For adjustments after this, disconnect the white clip and move the black cable housing towards the radiator an 1/8" at a time

If the TV cable adjustment doesn't fix the problem, then the pulse solenoid is malfunctioning. The (governor) Pulse solenoid (frequency valve) is notoriously bad on these transmissions and is used to govern the line pressure to smooth out shifts under light throttle. Since it shifts when requested (1st) and shifts down when I step on it harder, it is either a cable sensor adjustment or the solenoid that is bad.

If it never shifted automatically into first, it is the solenoid, but if it's intermittent, it's possibly just the cable. Only use Chrysler solenoids.

The problem is completely remedied by removing it and using a GM solenoid.

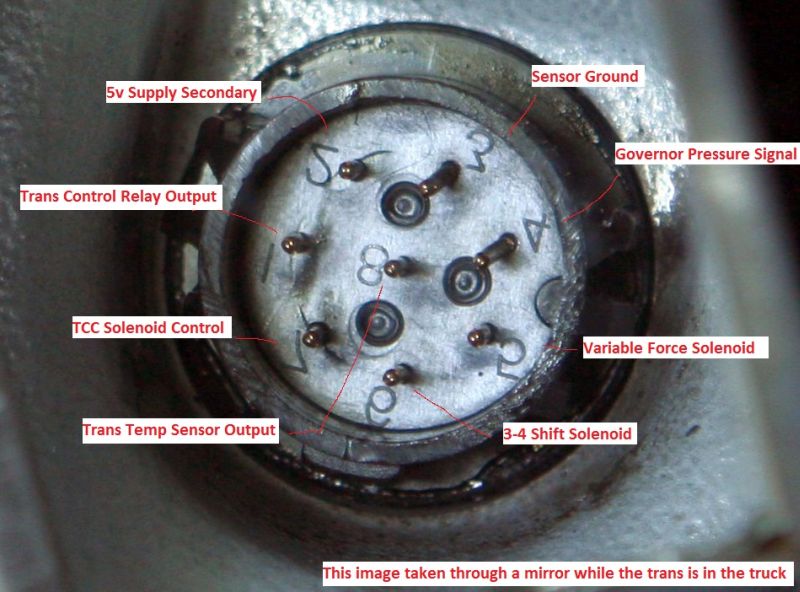

~120,000 miles Transmission Code Thrown

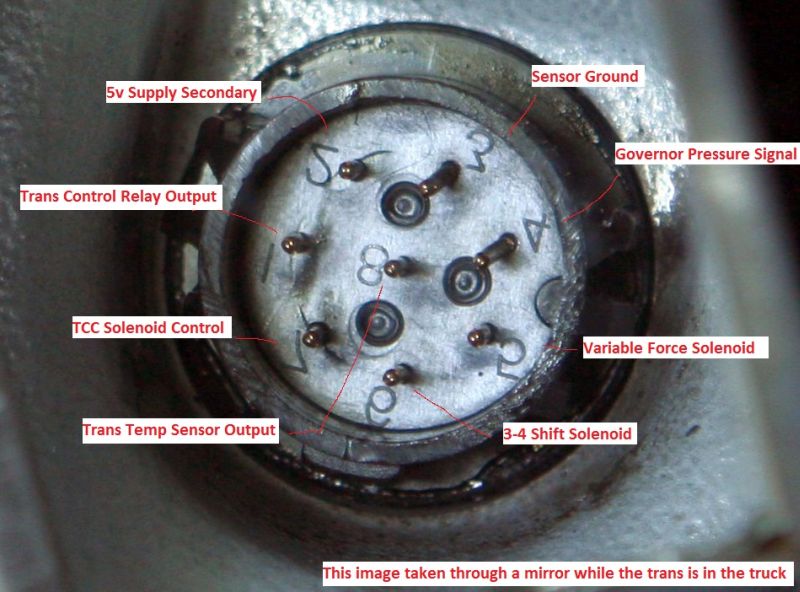

The cable adjustments weren't seeming to work. One day, the check engine light came on and the AutoTap pulled a P0753 code for the 3-4 shift solenoid/relay

circuit. The code doesn't automatically mean that the solenoid is bad. It could be an intermittent connection problem with either the internal or external

wiring harness. It could also be the PCM. If the PCM senses a problem with the transmission, it locks the transmission into 3rd gear and throws the shift solenoid code. So the code can just mean that the transmission is in limp mode. When the key is turned on, the PCM sends 12v down the overdrive lockout and torque converter solenoid

lines and expects to see 12v on the ground line. If it doesn't see that, it sets the code. The harness connector is of a bad design. If any gunk gets in

there or the pins are wet or don't make good contact, then a wiring fault will occur.

Many Chrysler products have bad electronics. (see

1995 Cirrus)

~120,000 miles Solenoid Connector Failure

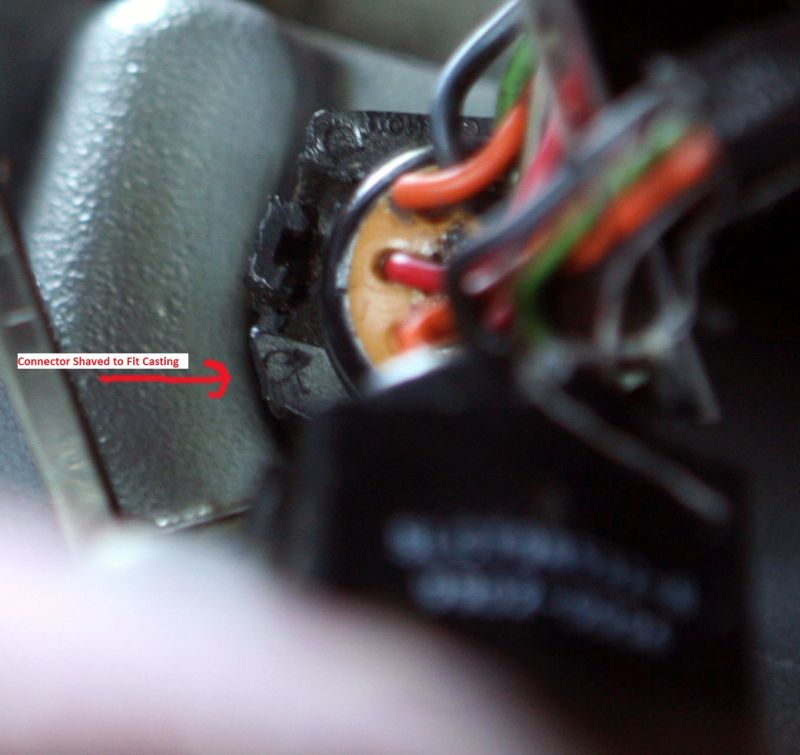

Click any image to see a higher resolution version

All of these images were shot through a mirror.

Below: Attempting to push the connector on with some help from safety wire and safety wire pliers

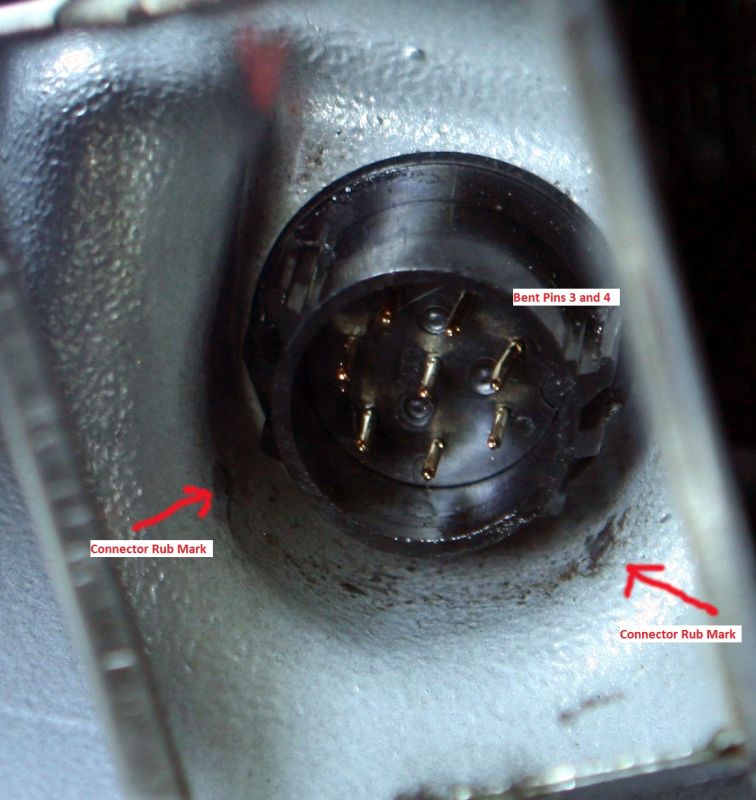

Below: The lower left corner of the connector is hitting the casting. The connector is just barely on the base, maybe 2 mm covered.

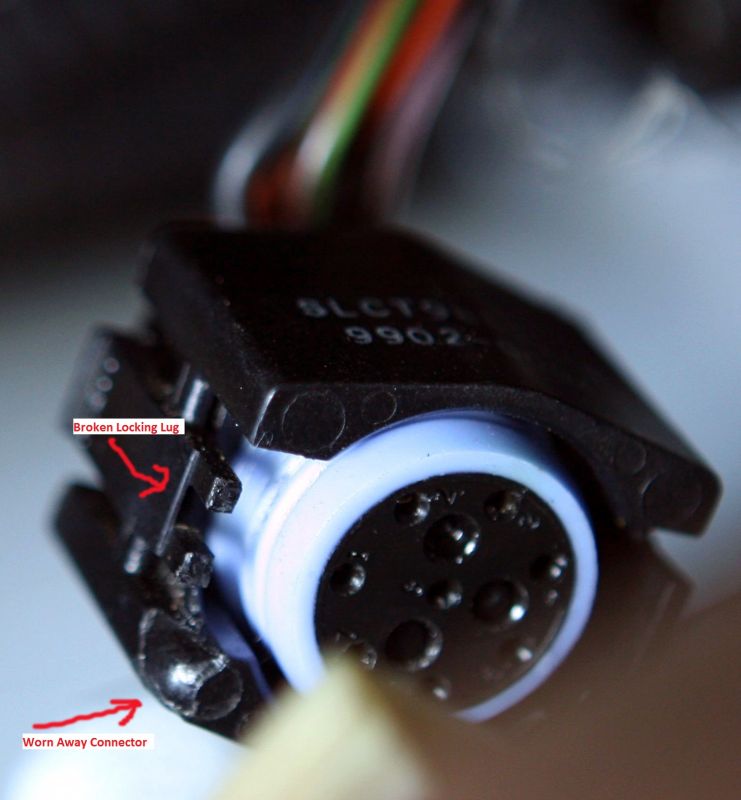

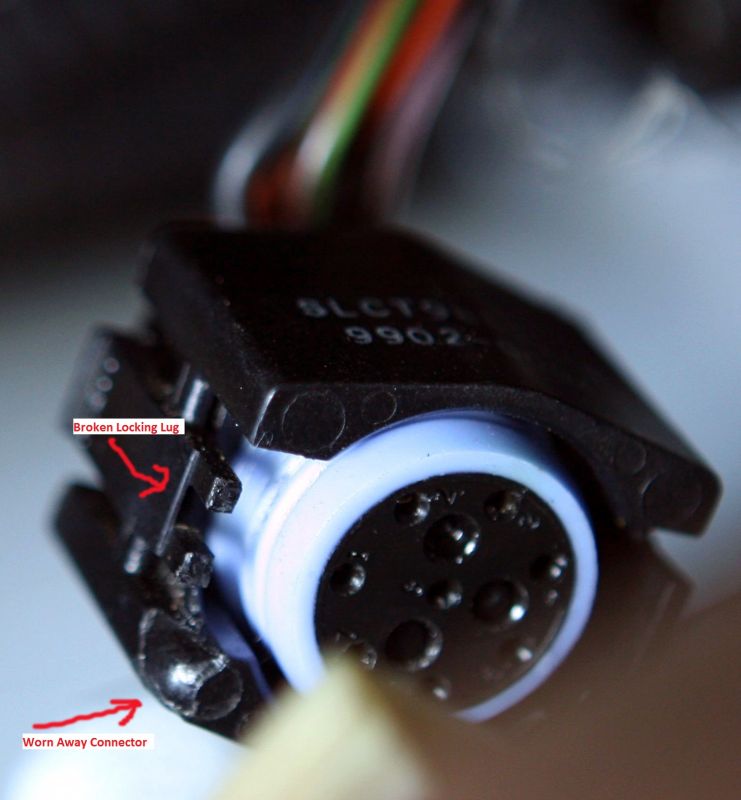

Below: The lower left corner or the harness connector tells the story - the corner has been worn away and the locking clip is broken.

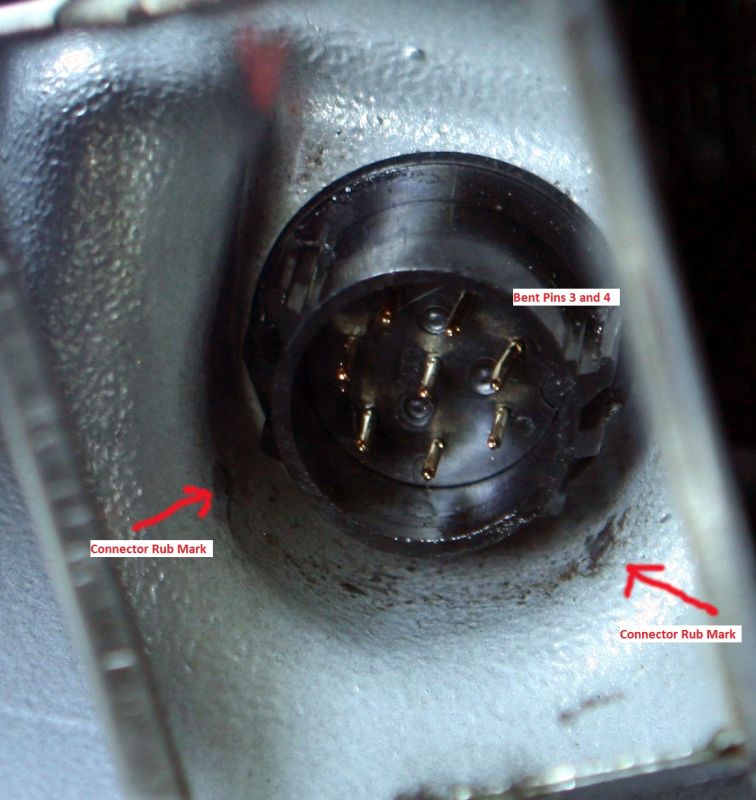

Below: It's hard to tell from this image, but the hole was machined off-center, so one side of the casting is too tight against the connector.

Below: The two black marks to the left and right and below the connector on the casting are from where the connector is rubbing on the casting.

They also show the total distance the connector was allowed to travel before stopping at the casting.

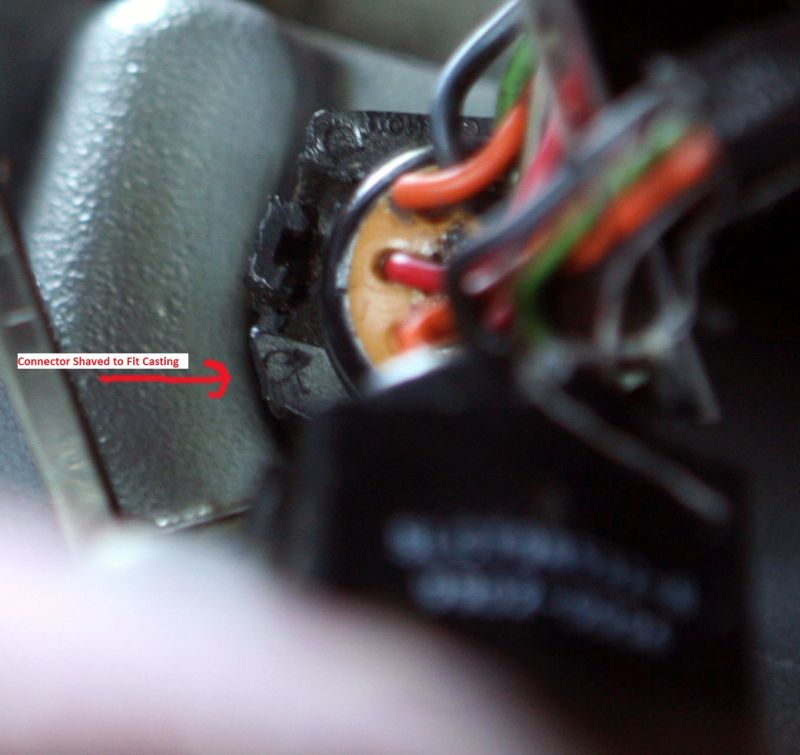

Below: After grinding the corner of the connector with a Dremmel tool, the connector slips down over the base.

Below: Another shot after the grinding.

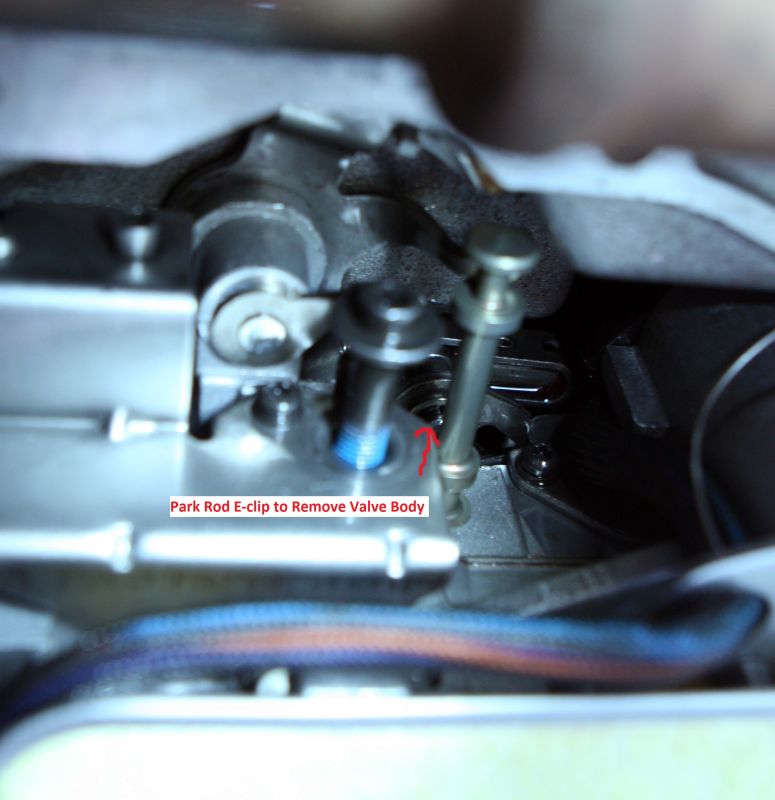

Below: Park Rod E-Clip (In focus, center, background)

~155,000 miles Transmission Codes Thrown

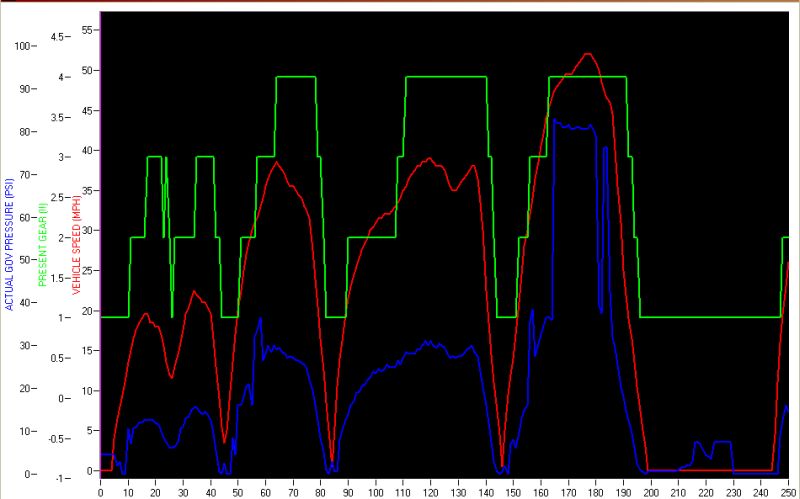

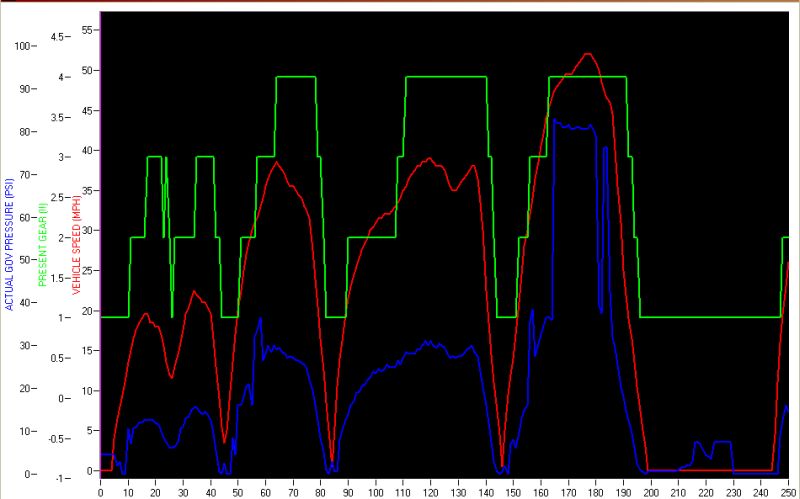

I started receiving an intermittent P1762 code. It actually happened once while I was OBD-II data-logging using my AutoTap scanner.

I don't know exactly how to interpret the results.

~156,000 miles Transmission Codes Thrown

I changed out the Governor Pressure Sensor and Solenoid and things got worse. The "Actual Governor Pressure" indicated is zero now, although the truck shifts normally. It is still sluggish. It feels like I'm starting out in 3rd gear, but the data log shows first gear.

P1762 and P1764 are now on continuously. My conclusion is that the connector is likely the fault. Unfortunately, Chrysler left no extra slack in the harness.

The connector barely is long enough to seat over the connector. Also, the important bits are not visible. I have to use a mirror to see anything.

~156,200 miles Transmission Codes Thrown

I went to Pick n Pull and found 6 or 7 Durangos. Out of those present, I identified the best 8 pin connector and pulled the pigtail. I then soldered the new

connector on, after shaving the sides of the connector so that it would snap on correctly. At this point, I'm still getting the pressure sensor codes. I'm going

to unplug the battery tomorrow and see if the codes go away. Clearing the codes with my Autotap didn't seem to work. I'll also run a data log to compare to the

one above.

Last update: Dec 7th, 2019